The purlin system connects the main structure and the roof ( wall) system, is an important part of the whole building system.

There are two types of Z-type and C-type cross-section.

Raw materials are hot-dip galvanized( Z275g / ㎡) , Q345 high-strength strip, high standard hot dip galvanized treatment, excellent anti-corrosion performance, computer numerical control drilling, high precision, with optimized cross-section design and continuous lap-joint design, to meet the long-span design requirements, safe and lightweight, easy installation.

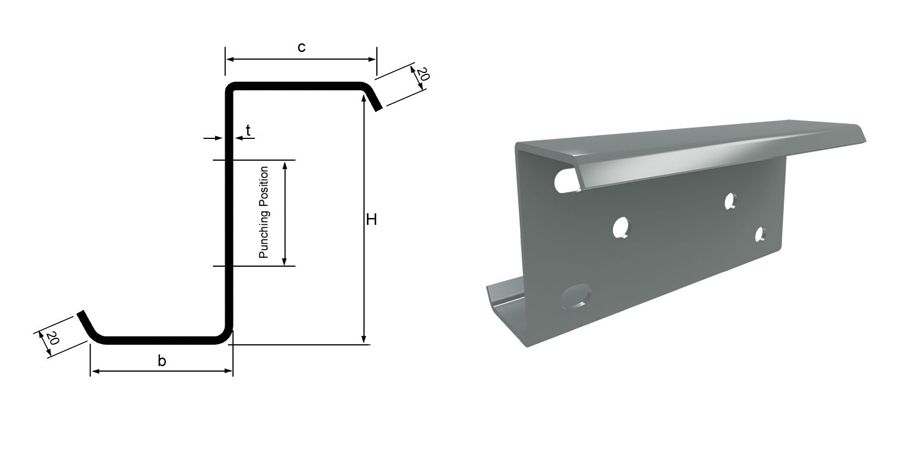

Advanced pre-punching technology:

The use of advanced pre-punching technology, aperture and hole drilling precisely in the factory through the CNC production line, no need to drill on the site, not only protect the purlin’s galvanized layer, to avoid rusting, extend service life. But also to make the purlin can be better connected with the plate, angle brace and rod support, easy to install, high accuracy.

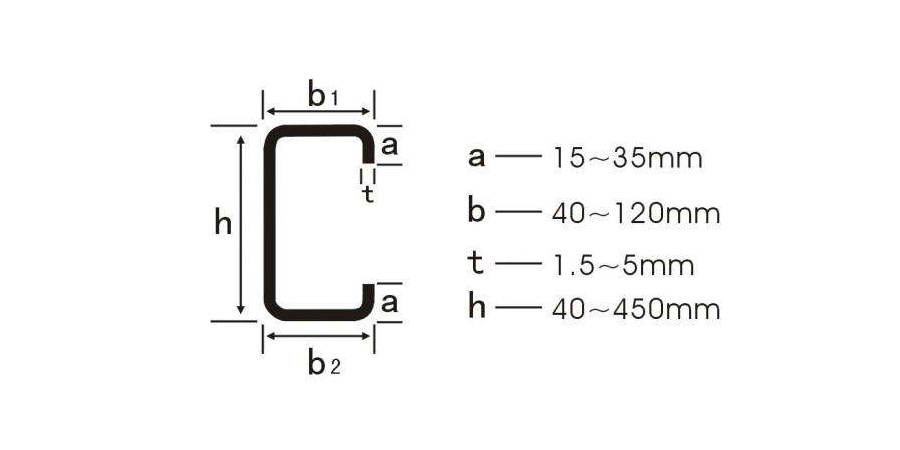

| Model | Cross Dimensions(mm) | ||||

| H | B1 | B2 | A | T | |

| C80 | 80 | 40 | 40 | 15 | 2.0-3.0 |

| C100 | 100 | 50 | 50 | 20 | 2.0-3.0 |

| C120 | 120 | 50 | 50 | 20 | 2.0-3.0 |

| C140 | 140 | 50 | 50 | 20 | 2.0-3.0 |

| C160 | 160 | 60 | 60 | 20 | 2.0-3.0 |

| C180 | 180 | 60 | 60 | 20 | 2.0-3.0 |

| C200 | 200 | 60 | 60 | 20 | 2.0-3.0 |

| C220 | 220 | 70 | 70 | 20 | 2.0-3.0 |

| C250 | 250 | 70 | 70 | 20 | 2.0-3.0 |

| C280 | 280 | 80 | 80 | 20 | 2.0-3.0 |

| C300 | 300 | 80 | 80 | 20 | 2.0-3.0 |

| Model | Cross Dimensions(mm) | ||||

| H | B | C | A | T | |

| Z140 | 140 | 55 | 50 | 20 | 2.0-3.0 |

| Z150 | 150 | 67 | 61 | 20 | 2.0-3.0 |

| Z160 | 160 | 67 | 61 | 20 | 2.0-3.0 |

| Z180 | 180 | 67 | 61 | 20 | 2.0-3.0 |

| Z200 | 200 | 67 | 61 | 20 | 2.0-3.0 |

| Z250 | 250 | 78 | 72 | 20 | 2.0-3.0 |

| Z280 | 280 | 78 | 72 | 20 | 2.0-3.0 |

| Z300 | 300 | 78 | 72 | 20 | 2.0-3.0 |