Integrated steel structure system solutions: from design to production and installation

As a leader of China’s steel industry, China PEB steel structure have been always committed to providing customers with a series of steel structure system solutions, more convenient services, technical advice, engineering design, program development, manufacturing and installation. China steel structure design and manufacture various types of steel structure system products for a variety of industries, multiple use, fully fit the different requirements of different customers.

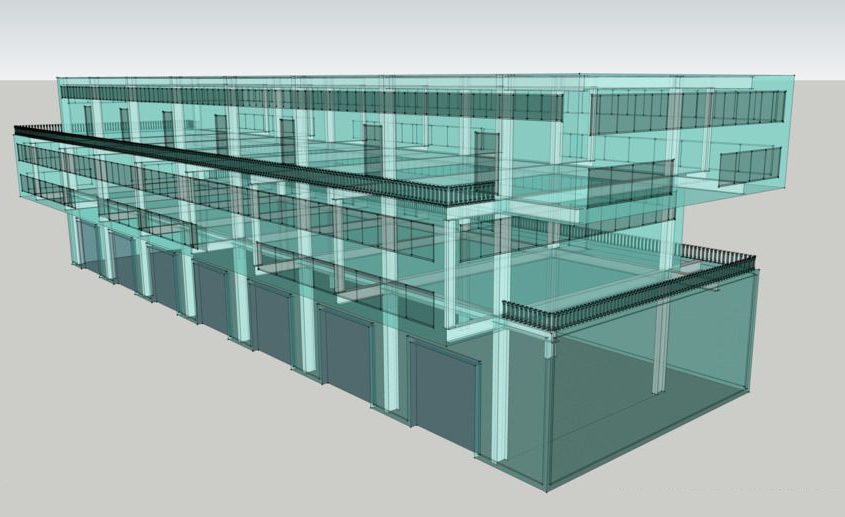

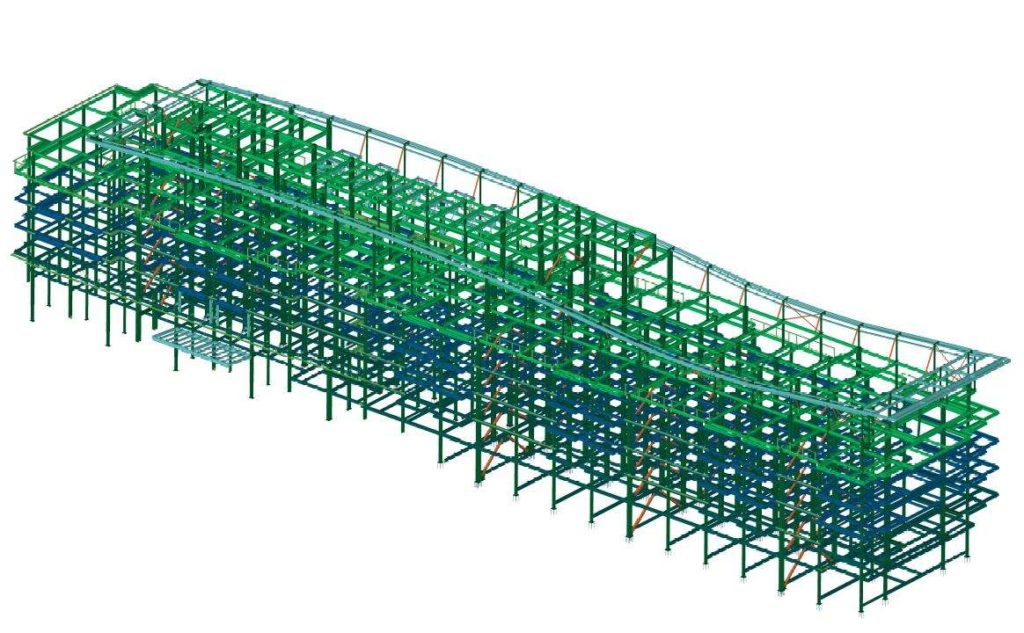

Light steel structure system on the basis of industrial buildings, warehouse, super market, multi-story steel structure buildings, is the oldest product of Brother Steel Structure, develop & research, design, manufacture, installation and service support are also our strength.

This construction system have advantages of large flat space, flexible layout, good economics; the roof system and wall system have strict performance requirements such as wind resistance, rainproof performance, sealing performance and anti-condensing water. Especially for the construction of various types of plant, logistics and other industrial buildings, as well as various types of large supermarkets, stores, cold storage and other commercial buildings.

Hotels, banks, office buildings, logistics, supermarkets, shopping malls, exhibitions, museums, hospitals, radio and television, communications, complex buildings, laboratory buildings, residential and other fields, to meet customer demand for architectural style diversification.

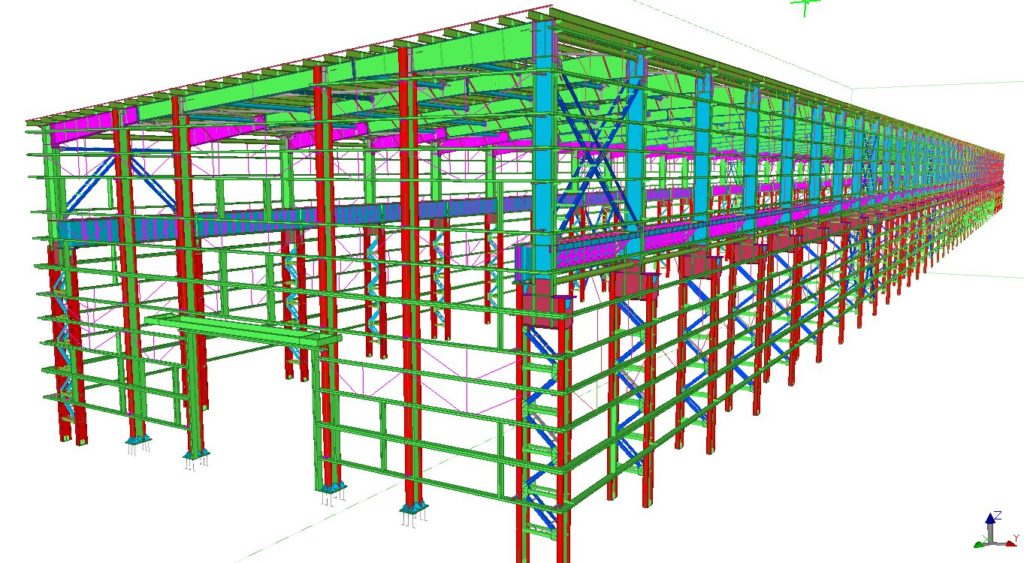

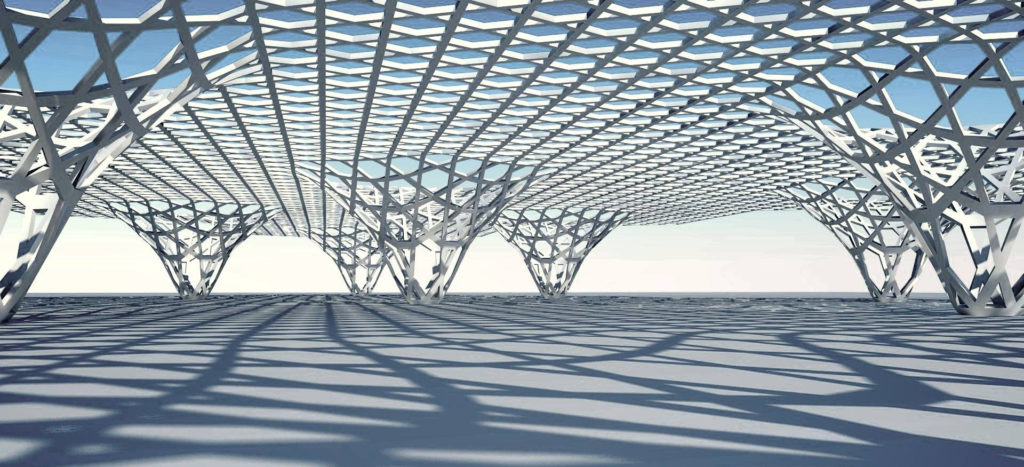

Structure related to steel structure, steel-concrete mixed structure, composite structure, etc; structural system involving steel frame structure, steel frame-support structure, steel frame-concrete cylinder structure, steel frame – concrete shear wall structure, Truss steel frame-support structure, steel frame with extensional truss- concrete cylinder structure, cylinder tube structure, giant support frame structure and so on. The maximum height is 381 meters, the largest single building area is more than 50 million square meters, the thickest steel plate up to 120 mm, the highest strength of steel up to Q460. Successfully handled a lot of special design, special materials, special process engineering problems, with a wealth of high-rise engineering experience.

Advantages:

1, light weight, high strength, the weight of residential buildings built with steel structure is about 1/2 of the concrete reinforced housing; meet the needs of large living room, the area increased by 4% comparing the concrete reinforced housing.

2, safety and reliability, good anti-seismic, wind resistance performance.

3, all the steel component are produced in factory, reduce on-site workload, shorten construction period, in line with industrial requirements.

4, reliable quality of steel structure factory products, accurate size, easy installation, easy cooperate with the relevant parts.

5, all the steel can be recycled, construction and removal process have less environmental pollution.

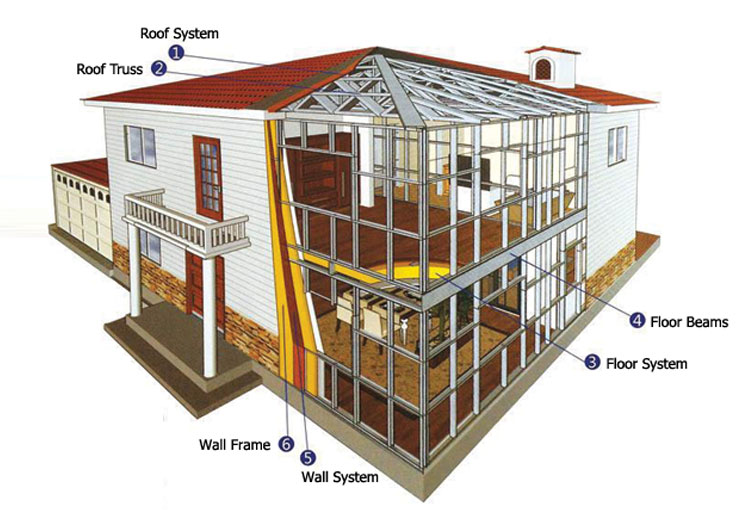

Main structure:

The structural system adopts steel frame – concrete cylinder system

The columns are made of high frequency welded square steel tubular columns

Beam using high-frequency welding H-beam

The frame beam are connected by a straight-through diaphragm-type rigid joint

The floor is made of reinforced concrete truss concrete cast or slab

Inside and outside the wall envelope system using the CCA board grouting wall

Steel components anti-fire system with thick coating type anti-fire retardant coating CCA board

Main feature:

Highly industrialized, strong industry traction, reduce social labor, improve social efficiency

Light weight, fast construction, short construction period (reduce 1/3 duration comparing the traditional way), significantly reduce the construction costs

Less concealed works, excellent construction quality

Less workyard, less energy consumption, reducing the dust, sewage, noise pollution to the environment

Small wall thickness, high room rate (8% higher than the traditional form), space transparent, flexible layout

Good anti-seismic performance, strong anti-fire, anti-theft ability, safe and reliable

Thermal insulation, energy conservation, saving daily expenses

Good Ventilation & lighting effect

High resource recycling rate, going green and environmental protection.