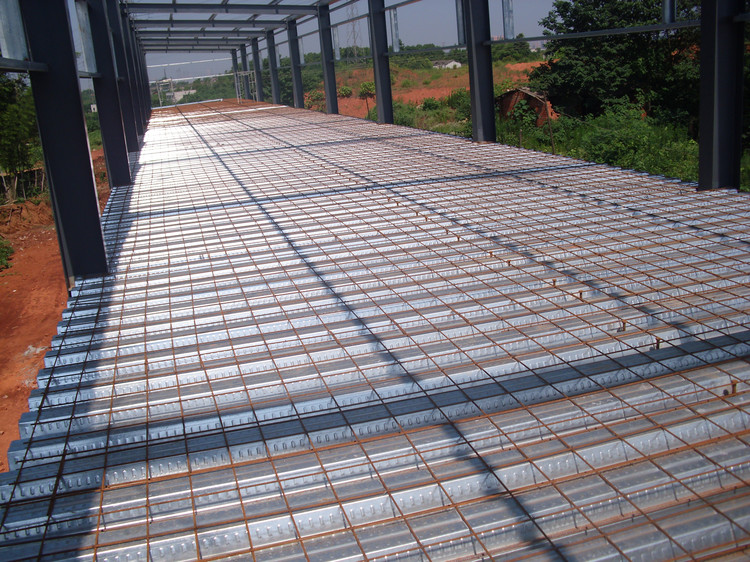

Steel decking system is developed according to the needs of steel and concrete composite structure, connect steel and concrete with scissors fittings, joint load carring, have both advantages of these two kind material, with the performance of light weight, high strength, strong stiffness, construction convenient and fast, easy to update, can be produce in the factory.

Advantages:

Better Durability

The China PEB steel base (floor deck) has superior corrosion protection(zinc content upto 275g/㎡) with guaranteed minimum yield strength depending on the specification used.

Unbeatable Strength

When the steel and concrete composite slabs are constructed, they are lighter and stronger than most conventional slabs. Steel decking provides flexible reinforcement, combined with the compressive strength of the concrete, for an all-round stronger slab. The steel decking profiles are designed to inhibit any longitudinal slip between the steel and concrete in the slab itself, and any transverse movement between the slab and the supporting beams.

Easy On-Site Handling

Steel decking is transported to site in pre-cut lengths, and in pre-packaged bundles. These bundles can be easily craned into specific work areas, and the individual sheets quickly laid by hand.

Speedy, Safe Construction

One advantage of metal deck steel flooring is its speedy erection. Another is that as the concrete slab is being poured progress is not hindered in other areas e.g. the floors above. China PEB is also able to offer stud welding and concrete flooring contractor services allowing the entire installation of the concrete slab to be undertaken by one skilled and experienced provider.

More Flexible Design

Steel decking can be varied in design and will give more strength, flexibility and efficiency..

Much Better Service Life

Steel decking will not twist and warp over time and is resilient to weather, moisture, time and pest deterioration.

China PEB is a manufacturer of metal decking in the China and has worked on a number of prestigious projects. We believe in providing a high quality service from design to installation to realize Clients’ requirements.

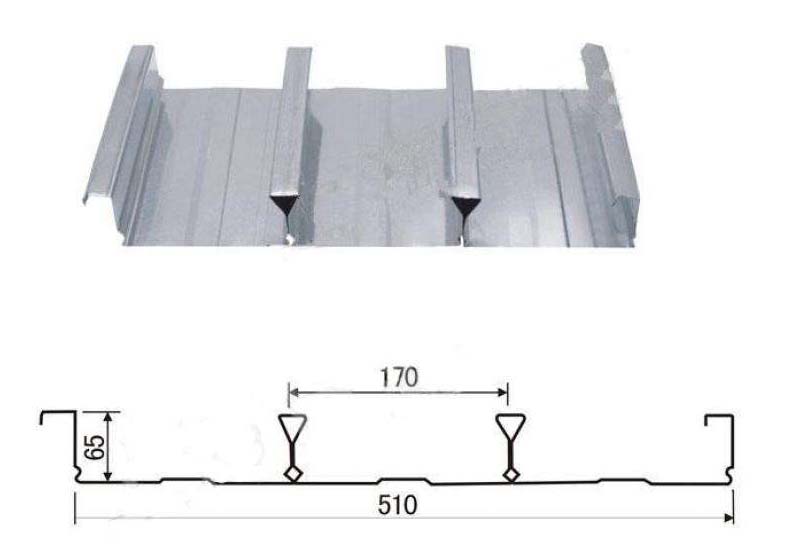

YX65-170-510

| Type | YX65-170-510 | ||

| Effective Width (mm) | 510 | ||

| Expansion Width (mm) | 1000 | ||

| Thickness (mm) | 0.8 | 1.0 | 1.2 |

| sectional inertia (cm4) | 49.4 | 61.78 | 74.14 |

| Sectional resistance (cm3) | 23.97 | 29.82 | 35.62 |

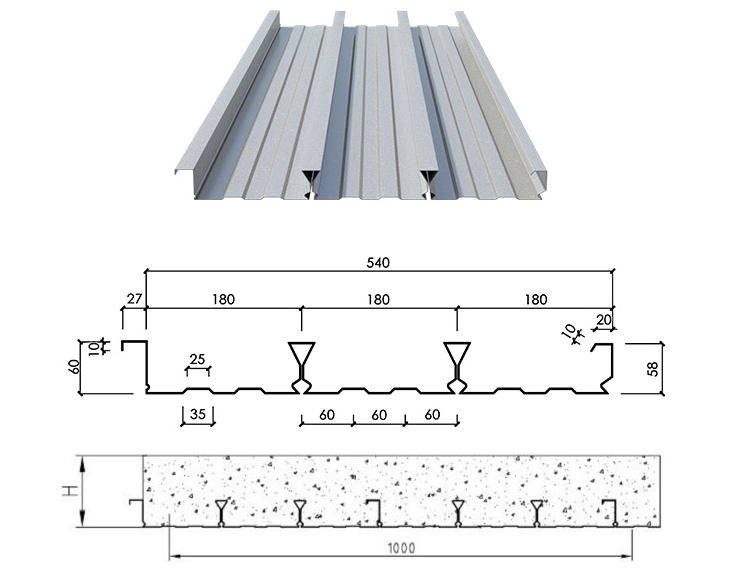

YX58-180-540

| Type | YX58-180-540 | ||

| Effective Width (mm) | 540 | ||

| Expansion Width (mm) | 1000 | ||

| Thickness (mm) | 0.8 | 1.0 | 1.2 |

| sectional inertia (cm4) | 49.4 | 61.78 | 74.14 |

| Sectional resistance (cm3) | 23.97 | 29.82 | 35.62 |

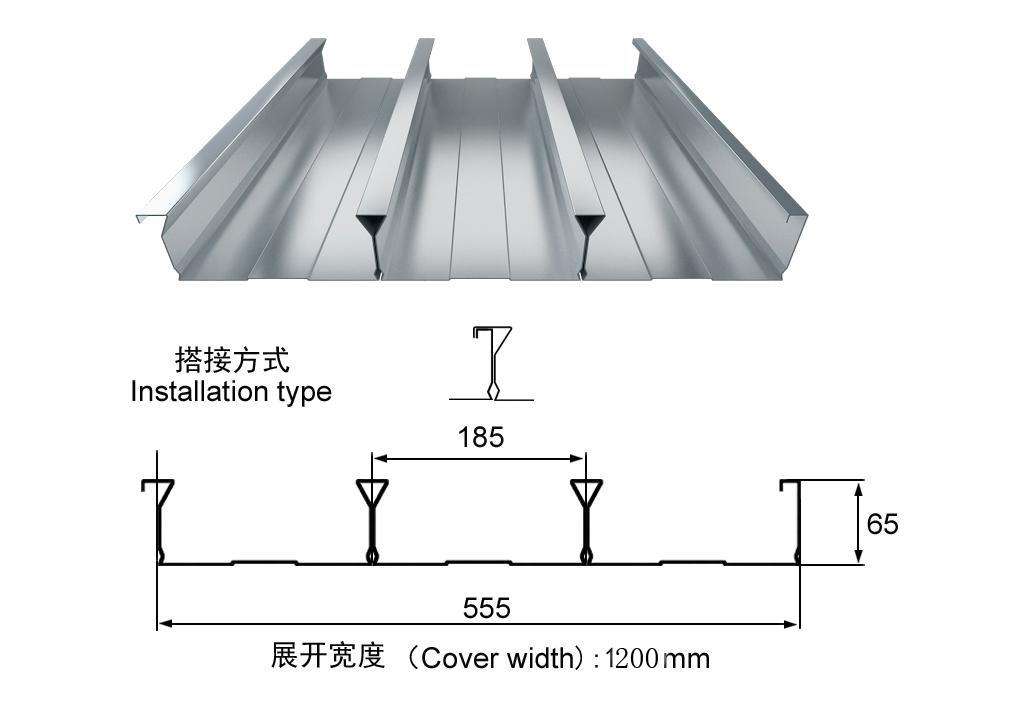

YX65-185-555

| Type | YX65-185-555 | ||

| Effective Width (mm) | 555 | ||

| Expansion Width (mm) | 1045 | ||

| Thickness (mm) | 0.8 | 1.0 | 1.2 |

| sectional inertia (cm4) | 49.4 | 61.78 | 74.14 |

| Sectional resistance (cm3) | 23.97 | 32.018 | 35.62 |

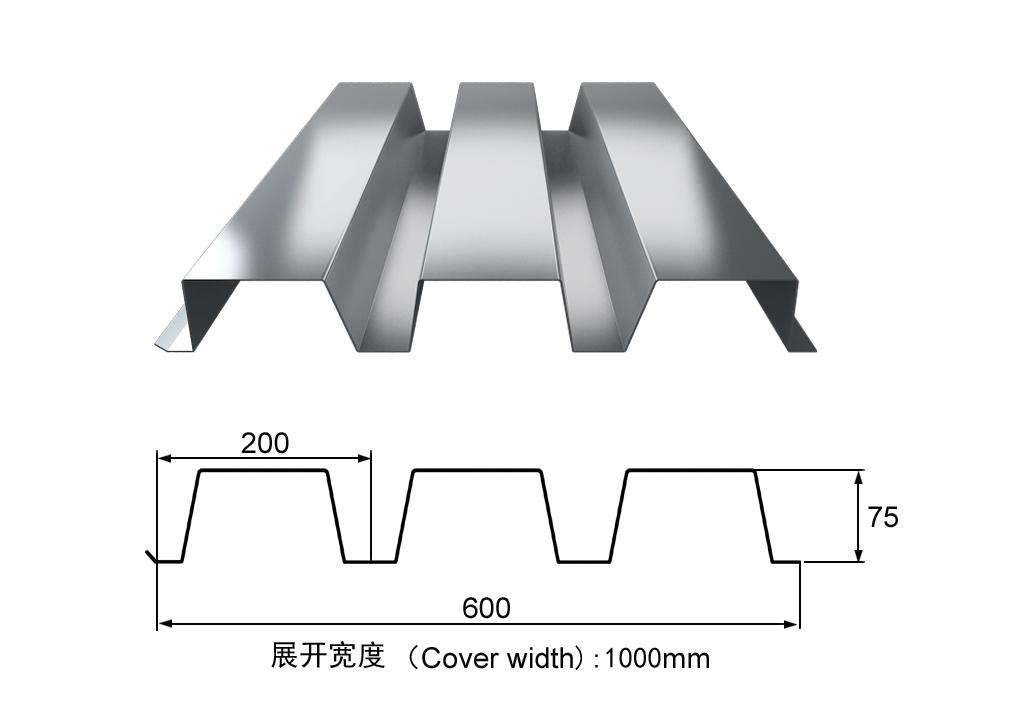

YX75-200-600

| Type | YX75-200-600 | ||

| Effective Width (mm) | 600 | ||

| Expansion Width (mm) | 1000 | ||

| Thickness (mm) | 0.8 | 1.0 | 1.2 |

| sectional inertia (cm4) | 105.10 | 157.70 | 189.2 |

| Sectional resistance (cm3) | 32.38 | 40.47 | 48.57 |

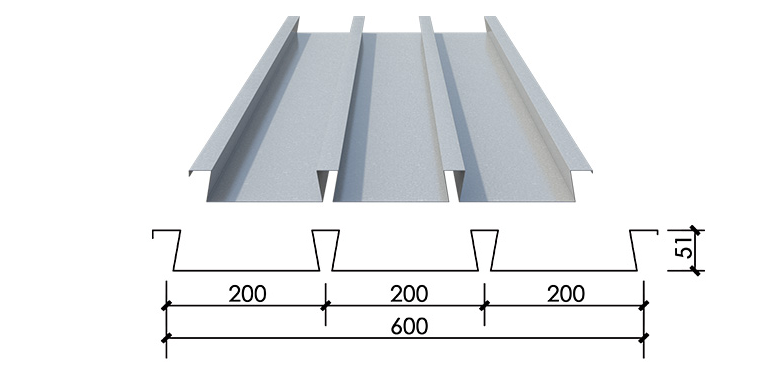

YX51-200-600s

| Type | YX51-200-600s | ||

| Effective Width (mm) | 600 | ||

| Expansion Width (mm) | 1000 | ||

| Thickness (mm) | 0.8 | 1.0 | 1.2 |

| sectional inertia (cm4) | 105.10 | 157.70 | 189.2 |

| Sectional resistance (cm3) | 32.38 | 40.47 | 48.57 |

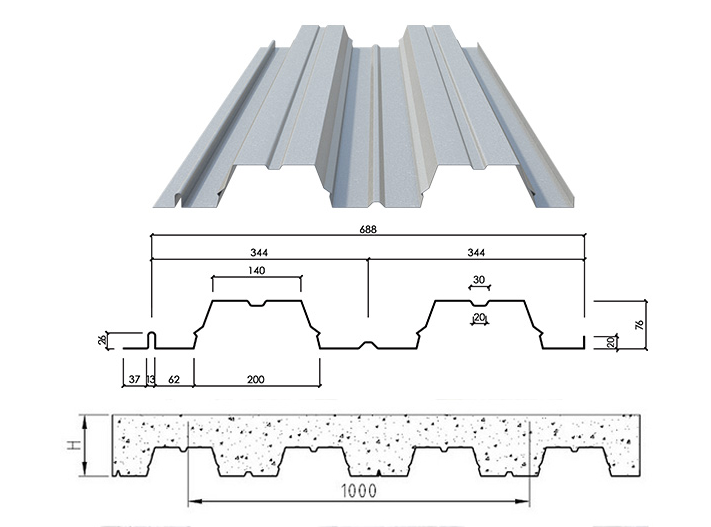

YX76-344-688

| Type | YX76-344-688 | ||

| Effective Width (mm) | 688 | ||

| Expansion Width (mm) | 1000 | ||

| Thickness (mm) | 0.8 | 1.0 | 1.2 |

| sectional inertia (cm4) | 91.62 | 119.38 | 142.01 |

| Sectional resistance (cm3) | 23.46 | 30.56 | 36.98 |

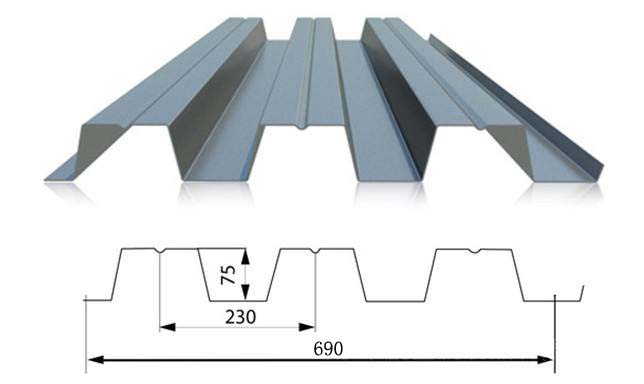

YX75-230-690

| Type | YX75-230-690 | ||

| Effective Width (mm) | 690 | ||

| Expansion Width (mm) | 1100 | ||

| Thickness (mm) | 0.8 | 1.0 | 1.2 |

| sectional inertia (cm4) | 126.20 | 157.70 | 189.2 |

| Sectional resistance (cm3) | 32.38 | 40.47 | 48.57 |

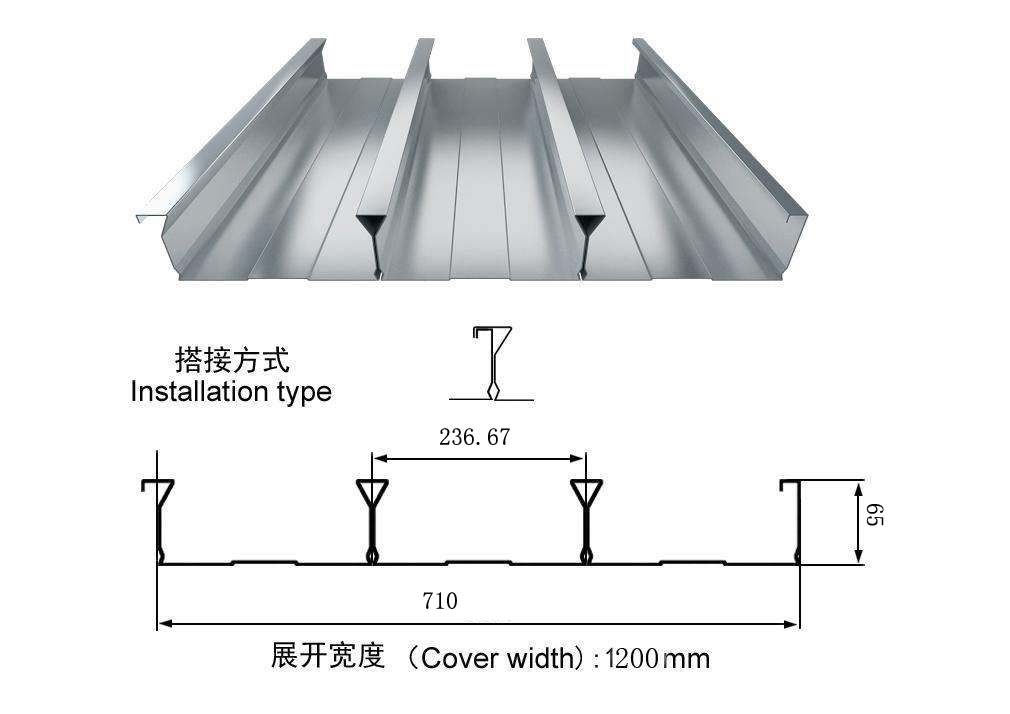

YX65-236.67-710

| Type | YX65-236.67-710 | ||

| Effective Width (mm) | 710 | ||

| Expansion Width (mm) | 1200 | ||

| Thickness (mm) | 0.8 | 1.0 | 1.2 |

| sectional inertia (cm4) | 126.2 | 157.7 | 189.2 |

| Sectional resistance (cm3) | 32.38 | 40.47 | 48.57 |

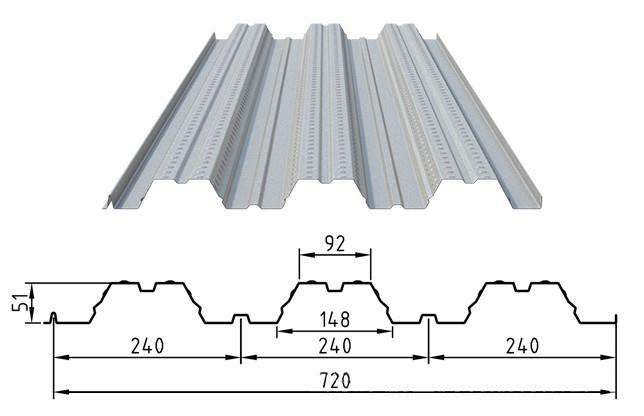

YX51-240-720

| Type | YX51-240-720 | ||

| Effective Width (mm) | 720 | ||

| Expansion Width (mm) | 1000 | ||

| Thickness (mm) | 0.8 | 1.0 | 1.2 |

| sectional inertia (cm4) | 52.80 | 64.55 | 76.38 |

| Sectional resistance (cm3) | 16.45 | 20.69 | 26.39 |

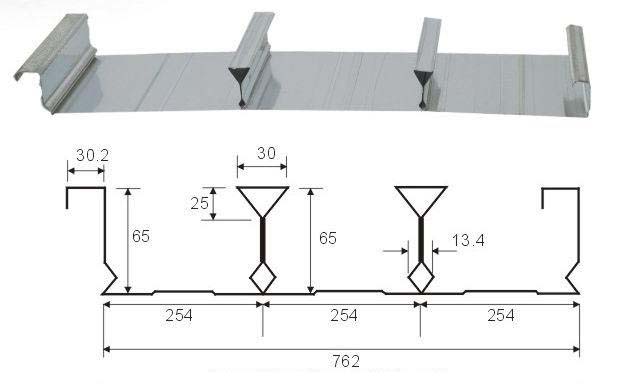

YX65-254-762

| Type | YX65-254-762 | ||

| Effective Width (mm) | 762 | ||

| Expansion Width (mm) | 1250 | ||

| Thickness (mm) | 0.8 | 1.0 | 1.2 |

| sectional inertia (cm4) | 126.2 | 55.07 | 82.62 |

| Sectional resistance (cm3) | 32.38 | 33.45 | 49.58 |

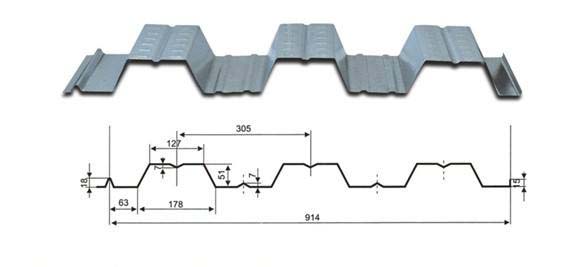

YX38-152-914

| Type | YX38-152-914 | ||

| Effective Width (mm) | 914 | ||

| Expansion Width (mm) | 1250 | ||

| Thickness (mm) | 0.8 | 1.0 | 1.2 |

| sectional inertia (cm4) | 51.94 | 70.6 | 189.2 |

| Sectional resistance (cm3) | 16.86 | 22.22 | 48.57 |

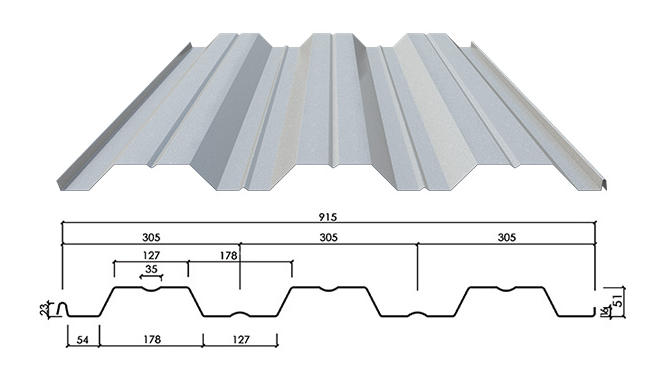

YX76-305-915

| Type | YX75-230-690 | ||

| Effective Width (mm) | 915 | ||

| Expansion Width (mm) | 1250 | ||

| Thickness (mm) | 0.8 | 1.0 | 1.2 |

| sectional inertia (cm4) | 91.362 | 114.21 | 137.06 |

| Sectional resistance (cm3) | 24.848 | 30.977 | 37.074 |