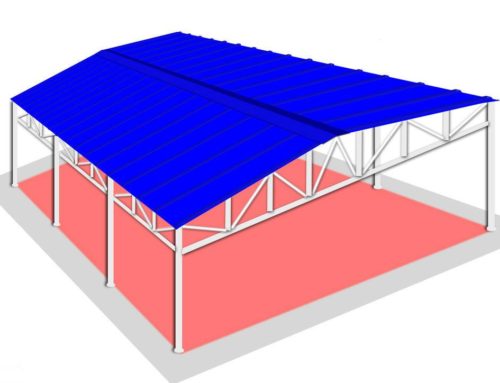

The main installation process of steel structure is as follows:

Surveying & positioning → embedded bolt in the foundation concrete→ (steel structure member processing) install the portal frame → crane railway installation → installation of steel girders → roof trusses, roof panels and eave installation → wall panel installation → steel coating.

Steel structure installation

1. Construction methods: first review the axis of the concrete foundation and he top elevation. Then lifting all the steel columns one by one, and fixed it after correction, after that install the steel beams, adjust the location before fixed, install the roof truss and purlin system in the end.

2. Construction sequence: The field can be divided into pieces if the area is too big, for normal project, it can be installed from one end to another. The crane should have enough lifting capacity.

3. Preparation before installation

3.1. Check the positions of the column bolts(anchor bolts).

3.2. Prepare the installation progress plan and component supply plan, organize the construction.

3.3. Check the steel components: check the documents, such as certificate of qualification, drawings, technique agreements, etc. The steel components should be unloaded near the installation point, where don’t affect the installation and convenient for the installation.

3.4. Installation quality standards in accordance with the design requirements, the installation error is usually not more than 1/1000.

4. Installation technology

4.1. Steel column installation process: before lifting the component(steel member), need to confirm the location of lifting points and the fixed mode, and prepare protection measures. After lifting the steel column, correct the position when the bottom of the column is up high of the bolts about 30-40CM, let the column centre the anchor bolts, loosen the lifting rope( steel wire rope) when the column at the right position. After the initial correct, get rid of the rope while the vertical deviation is under 20mm.

4.2. steel girder (beam) installation: Lifting the steel beam after fixed the steel column, slow down when the bottom of the beam is 100mm higher than the top of column, correct the position of the steel beam before fixed the bolts and nuts. During the lifting, surveying with theodolite, adjust the deviation and made it in accordance with the design.

4.3. Wall purlin installation: because the purlin has small section, light weight, can be lifted by manpower. Need to be measure the spacing between purlins, and need to be confirm the positions. Loosen the bolts and nuts if there is some error.

4.4. Roof purlin installation: steel purlins, due to light weight, the installation can use crane or manpower. After finished the installation of a unit of steel columns and roof beams, you can carry out the roof purlin installation. Purlin installation error should be within 5mm.

5.Installation correction

5.1. Steel column correction: steel column vertical correction with the theodolite or hanging hammer test, when there is a deviation need to correct with jack, elevation correction use jack to raise the base, and then increase or decrease the thickness of the steel base plate, fasten the nuts immediately after corrected, pouring fine stone concrete to fixed the column.

5.2. Steel beam correction: correct the steel beam axis and vertical, correction using jack and chain fall, fixed immediately after corrected.

Leave A Comment