Industrial workshop is a variety of housing which directly used for the production or supporting the production, including the main workshop, auxiliary space and ancillary facilities. All industrial, transportation, commercial, construction and scientific research, schools and other units are all these kind.

The Definition Of Industrial Workshop

The industrial workshop is building that used for production, including the processing workshop and the annex, such as power distribution room, water supply house, sewage and other supportive housing.

The Classification Of Industrial Workshop

(A) Classify according to the structure and supporting plant:

Single / multi-layer, with or without the overhead crane, with or without power distribution, with or without water supply, with or without sewage.

(B) Classify according to the characteristics of product manufacturing, industrial workshops can be broadly divided into the following three types:

(1) General Production workshop: A workshop producing under normal conditions.

(2) Explosion and fire hazard production workshop: producing or store goods which may have explosive and fire hazards.

(3) Workshop in a harsh environment: dusty, damp, high temperature or steam, vibration, smoke, acid or alkali corrosive gases or substances, radioactive substances.

The Features

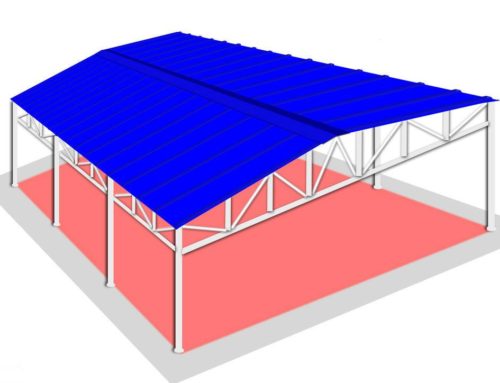

According to the building style, industrial workshops can be divided into single-story industrial constructions and multi-story industrial buildings.

The vast majority of multi-story industrial buildings are used in light industry, electronics, instrumentation, communications, pharmaceutical and other industries, such kind of workshop floors are generally not very high, and its lighting design are just like common scientific research building’s, and most of them used fluorescent lighting system.

Production workshop in the fields of machining, metallurgy, and textile are generally single-story industrial buildings, and according to the needs of production, most of them are multi-span single-floor industrial buildings, that is, the multi-span buildings arranged in parallel with each span as needed, which height can be the same or different.

The single-story plant needs to meet the requirements to determine the span(width ), length, height based on a certain building modulus.

Workshop Span S: generally 6,9,12,15,18,21,24,27,30,36 m …….

Length L: ranging from tens of meters to hundreds of meters.

Height H: 5 ~ 6m, high up to 30 ~ 40m, or even higher.

The span and height of the workshop are the main factors which should consider in the plant lighting system design.

In addition, according to the continuity of industrial production and the need for product transportation between sections, most industrial workshops are equipped with cranes, which can be 3 ~ 5t in weight and up to several hundred tons in large scale (currently, the weight of a single cranes in the machinery industry up to 800t).

Design:

Industrial workshop design standards are based on workshop structure style, the design needs to meet the requirements of process and production conditions.

Standard workshop design specifications:

First, the industrial workshop design must meet the relevant national guidelines and policies, adopt advanced technology, reasonable cost, safety and easy to use, quality guaranty, in line with the requirements of energy conservation and environmental protection.

Second, this standard can apply to the design of new construction and reconstruction, and expansion of industrial workshop, but does not apply to the biological clean room which operating bacteria.

The provisions of this Code relating to fire prevention and evacuation and fire protection facilities do not apply to the design of high-rise industrial buildings which height exceeding 24 meters and underground industrial buildings.

Third, reconstruction the original building with clean technology, industrial workshop must design based on the production process requirements, according to local conditions, different treatment, make full use of existing technology and facilities.

Fourth, the design of industrial workshops should create the necessary conditions for the construction and installation, maintenance and management, testing and safe operation.

Fifth, beyond that the design of the industrial workshop should in accordance with the Code, it should meet the current national standards, norms of the relevant requirements.

Steel workshop design standards

These standards are aimed at to make the steel components easy to manufacturing, make the size of the steel members to achieve standardization and serialization.

This standards applies to:

First, the design of assembly or partial assembly of reinforced concrete structures and mixed structure workshop;

Second, the preparation of workshop building accessories standard design atlas.

Note:

① The design of steel structure workshop, modified (expanded) construction workshop subject to conditions, cast-in-place reinforced concrete structure workshop, workshop with special requirements, or technically and economically significant unreasonable workshop which design under these standards, may not implement some of the provisions of these standards;

② Workshop that use new technologies, new structures and new materials, may not be subject to certain restrictions of these standards.

In one construction site, when determine the design of the workshop, should make the type of construction parts uniform.

On the basis of technical and economic rationality, the shape of the workshop should be simple, and avoid different heights between different spans.

In the preparation of workshop components standard design atlas, should use the same configuration to make sure the maximum interchangeability.

In addition to the workshop design should meet the relevant provisions of these standard, also should be consistent with the existing provisions of the relevant national standards.

Leave A Comment