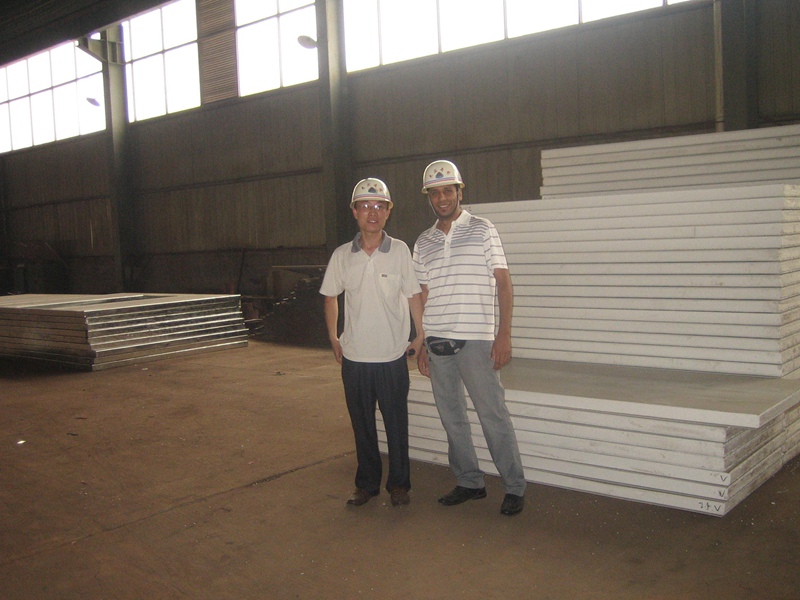

Our Happy Clients

These are some of our clients, they are from Austrilia, Angola, Middle East, some Africa countries, etc.

Some need to build workshops, some need steel platform, steel bridge, steel framework, some need to build steel structure housing, some need steel frame villa. There are a lot of suppliers, maybe cause of our good service, integrated solutions, in a number of comparison, they chose us finally. Maybe our price is not the best, but always there is flash point, make them feel important.

Domestic Clients

With our excellent design standards, manufacturing processes and technology, automotive, food, daily necessities, heavy industry, and many other industry customers, then finally choose to cooperate with us. The following is some of the partners.

Zoomlion Heavy Machinery Co., Ltd. was founded in 2011 and its predecessor was Chery Heavy Industry Co., Ltd. merged into Zoomlion in August 2014. Zoomlion Heavy Machinery Co., Ltd. is specialized in research, development, manufacture, sale, logistics and service of or for agricultural equipment. It is one of the five strategic sectors of Zoomlion.

Zoomlion Heavy Machinery Co., Ltd. was founded in 2011 and its predecessor was Chery Heavy Industry Co., Ltd. merged into Zoomlion in August 2014. Zoomlion Heavy Machinery Co., Ltd. is specialized in research, development, manufacture, sale, logistics and service of or for agricultural equipment. It is one of the five strategic sectors of Zoomlion.

Zoomlion Heavy Machinery Co., Ltd. strives to be a leader in providing all-process solutions for agricultural equipment. By September 2014, the agricultural equipment sector of Zoomlion Heavy Machinery Co., Ltd. had become one of Top 3 in the domestic market: No. 1 for market share of low-temperature recirculation dryer and one of leaders in terms of tractor and rice, corn & wheat harvesters.

Zoomlion Heavy Machinery Co., Ltd. is headquartered in Wuhu, Anhui Province; some business bases are under construction in the headquarters and the provinces of Henan, Zhejiang, Jilin and Xinjiang; the Overseas Business Unit is situated in Beijing. Adhering to the tenet “Technology Changing the World, Wisdom Creating the Future”, we’ll put Zoomlion Heavy Machinery Co., Ltd. into a world-class agricultural equipment brand with global competitiveness based on independent innovation by integrating the global resources.

San Yang Textile Co., Ltd. was established in 2003. It is a joint-stock enterprise with 45,0000 spindles combing spinning and 400 sets of air jet loom, which is a main production capacity of large textile group. San Yang Textile Co., Ltd. has 5 subsidiary companies, which owns equity worth RMB20 billion , 2,500 employees; It also establishes branches in different provinces & abroad and formed 5 marketing division to manage 20 offices. Overseas markets throughout Europe, United States, Japan, Korea and other countries.

The company adheres to the strategic orientation of high-end outward. On hardware side, we configure Switzerland, Italy, Germany, United Kingdom, Japan and other international top technical equipment; establishment of a state owned Technical Center and the International Assured Uster lab. It configures the full complement of Switzerland Uster five test equipment, the introduction of United States cotton company EFS with cotton system to ensure product quality stability. On software side, the company in response to the financial crisis during the differentiation of a series of reforms that promote patterns and mechanisms of constantly upgrading, enabling help enterprise passed the most severe ordeal.

According to the “production a small amount of product, service a small number of customers” product positioning, the company mainly produces high count cotton combed yarn, compact yarn and high-grade fabric, is committed to the “High-Strength, White Guarantee” research and promotion, the production of tenacity yarn and white guarantee yarn with the industry’s relatively high visibility; The SUPIMA tag is launched in 2009’ and majority of our customers are unanimous of it. For several years, we have received an award such as “The Agricultural Development Bank Most Valuable Customer” and “China Cotton Textile Industry Most Competitive Top 20 Enterprises”; in combed yarn products have received “China Famous Brand” award.

San Yang Textile Co., Ltd. always persists in “Service High-End, Trend-Setting”, “Differentiation and Intensive” as development ideas. We constantly promote industrial upgrading and management upgrading, and try to be one of the high-end textile enterprises in China.

Shandong Shouguang Juneng Special Steel Co., Ltd. is a large enterprise majoring in special steel bars and OCTG. Currently, the company consists of six mills including sintering mill, iron-making mill, steel-making mill, bars hot rolling mill, pipe mill and power plant, as well as eighteen function departments. The company has a total capital of 5 billion RMB.Covering an area of 1.65 million square meters, employing over 4500 people including more than 700 technical professionals and being equipped with national level lab and provincial level enterprise technology center, the Company is the test foundation for Central Iron and Steel Research Institute for new process, new technology, new materials and new equipment. Now the company has an annual productivity of 2 million tons of special steel bars and high level OCTG.

The major products of the company cover ten series of steel including high quality carbon structure steel, alloy structure steel, pipe billet, steel for drill rod, steel for ship anchor chain, spring steel, bearing steel, carbon tool steel, oil casing pipe and line pipe. Among above products, bearing steel, high quality carbon structure steel, high strength bolt steel, round bar for ship anchor chain, casing pipes for oil and gas industry were awarded with Provincial Excellent Product of Shandong; round bars for ship anchor chain have obtained the certificates of eight countries’ ship classification societies such as LR of the UK, NK of Japan, ABS of the US, DNV of Norway, BV of France, GL of Germany, KR of South Korea and CCS of China; pipe billet for medium and high pressure boiler and pressure container, bearing steel and HRB for reinforced concrete have got the production license from the SIQSAQ. Seamless pipes have obtained the production license from the SIQSAQ and got the API license. As certified supplier of CNPC and permitted member of the supply management comprehensive information platform of Sinopec, the company has become one of the major enterprises for Chinese oil and petroleum equipment industry foundation. The company was recognized to comply with the National Iron and Steel Enterprise Regulation. The company has become an important production foundation of special steel in Shandong Province, with its products exported to Japan, South Korea, Middle East, Europe, US and African countries, and widely used in agricultural machine, oil and gas industry, chemical industry, railway, mining industry, automobile industry, ship industry and machining manufacturing industry.

During its development, the company insists on human-oriented value and green development concept. It optimizes the talents improving mechanism, continuously invests in environmental protection program, actively carries out energy conservation and pollution reduction policies, and has achieved maintainable development. The company was recognized in precedence as National Iron and Steel Industry Excellent Enterprise, Enterprise that Abides by Contracts and Keeps Promises, Standard Enterprise that fulfills social responsibilities and AAA Level Enterprise in Credit recognized by Credit Assessment of Enterprises in Shandong Province.

Jiangsu Sunshine Group was founded in 1986 and now employing more than 15,000 staffs. The company sets foot in many industries like wool Textile, Garment, Biological Pharmacy, Real Estate, Thermal Electricity power-supply and New Energy etc. The Textile business has annual production capacity of 3.5 million sets of high-grade men’s suits and women’s wear, 35 million meters of superfine worsted wool Fabrics. It is the world’s largest wool Textile manufacturer and high-grade apparel production base, and the only enterprise in China Textile industry who won honorable title of ‘World Brand’ and ‘Garment Export Inspection Exemption’.

“Sunshine” is the first famous trademark of China in worst wool Textile industry. “Sunshine” brand was awarded Specially Fostered and Developed Name Brand Of China by Commerce Department. In 2007, the International Organization for Standardization / Technical Committee Textile (ISO/TC38) set up its International Secretariat in Sunshine. Sunshine became the first domestic enterprise to undertake the work for ISO international secretariat, which marks Sunshine Textile technology reached international advanced level.

In 2008, new brand Sunshine fashion opened its first stores in Shanghai and Nanjing, it will expand 300 stores across the country in the next three years, marking Sunshine’s direct enter into retail market. In December 2008, 1,500 tons of polycrystalline silicon production project was successfully put into operation and become a new economic growth point of the Group. In 2008, the Group achieved sales of 23.6 billion yuan, 399 million USD export volume, 2.2 billion yuan tax and profits. For 22 years, Jiangsu Sunshine Group firmly establishes scientific development concept. It vigorously implements science and technology innovation and sustainable development strategy. It adheres to brand building as the basis, it enhances the core business and improves diversification of the industry chains as the development direction, It makes use of intangible assets during brand accumulation, therefore Sunshine take the road of diversified development. With the main business bigger and stronger in wool. Textile and Garments, Sunshine are involving in bio-medicine, Real Estate, New Energy, thermoelectricity power industries, so that “Sunshine” brand are given with more science and technology content and development potential.